Introduction

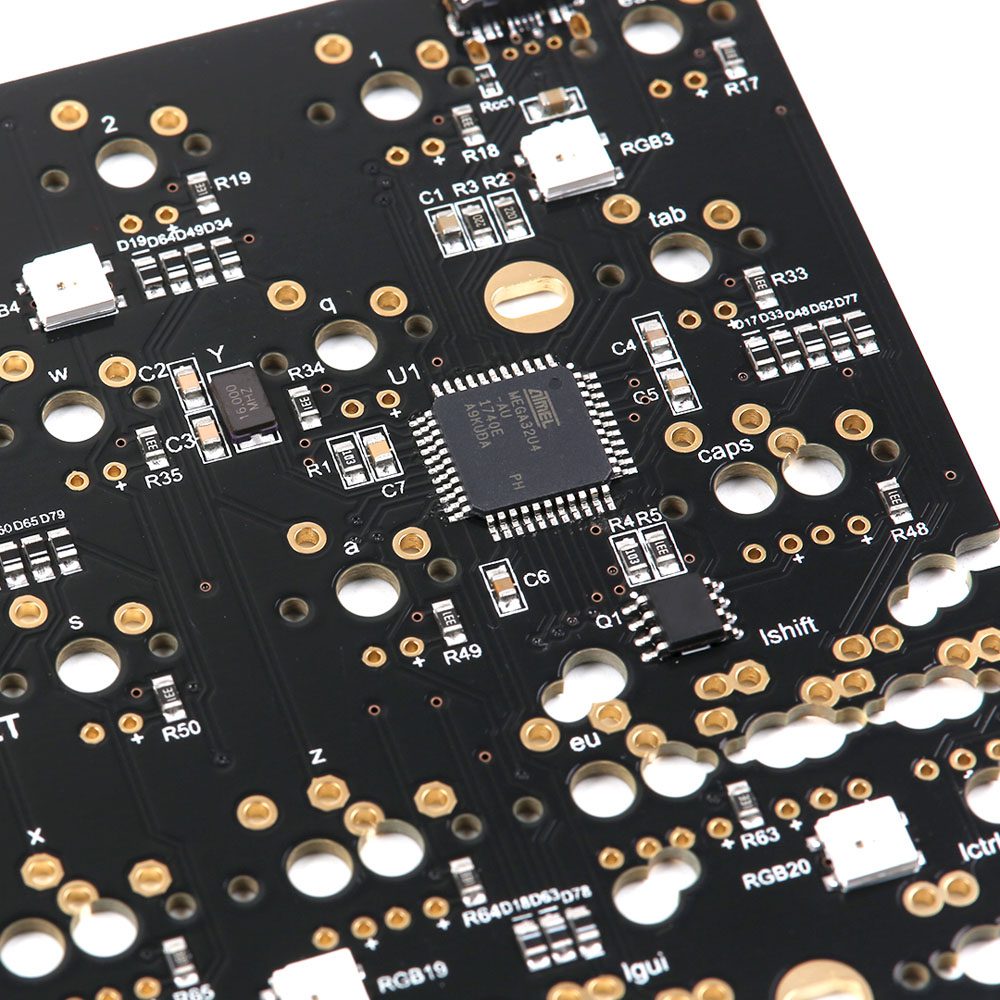

Keyboard PCBs (Printed Circuit Boards) are the backbone of any keyboard, providing a platform for all the components to be connected and communicate with one another. Keyboard PCBs play an essential role in ensuring keyboards work properly and meet user requirements. Keyboard PCBs come in various sizes and shapes, depending on the type of keyboard being built. Keyboard PCBs must also be designed to meet specific standards set by manufacturers or industry organizations such as USB-IF or Bluetooth SIG.

Keyboard designers need to consider factors such as power consumption, signal integrity, physical size constraints, cost effectiveness, and ease of assembly when designing their Keyboard PCBs. With so many considerations that go into creating a Keyboard PCB it is important that designers have experience working with these components in order to ensure they create the most efficient design possible.

What is Keyboard PCBs and their importance

Keyboard PCBs (Printed Circuit Boards) are one of the most important components of any keyboard, providing a platform for all the other elements to be connected and communicate with one another. Keyboard PCBs come in various shapes and sizes, depending on the type of keyboard being built. Keyboard designers need to take into account several factors when designing Keyboard PCBs, such as power consumption, signal integrity, physical size constraints, cost effectiveness and ease of assembly.

The most important factor when creating Keyboard PCBs is ensuring that they meet specific standards set by manufacturers or industry organizations such as USB-IF or Bluetooth SIG. Keyboard PCBs must also include features that allow users to interact effectively with the keyboard – this could include tactile feedback, tactile recognition or haptic feedback capabilities. Keyboard PCBs should be designed to ensure maximum efficiency and user experience; this includes making sure they are durable enough to withstand long-term use.

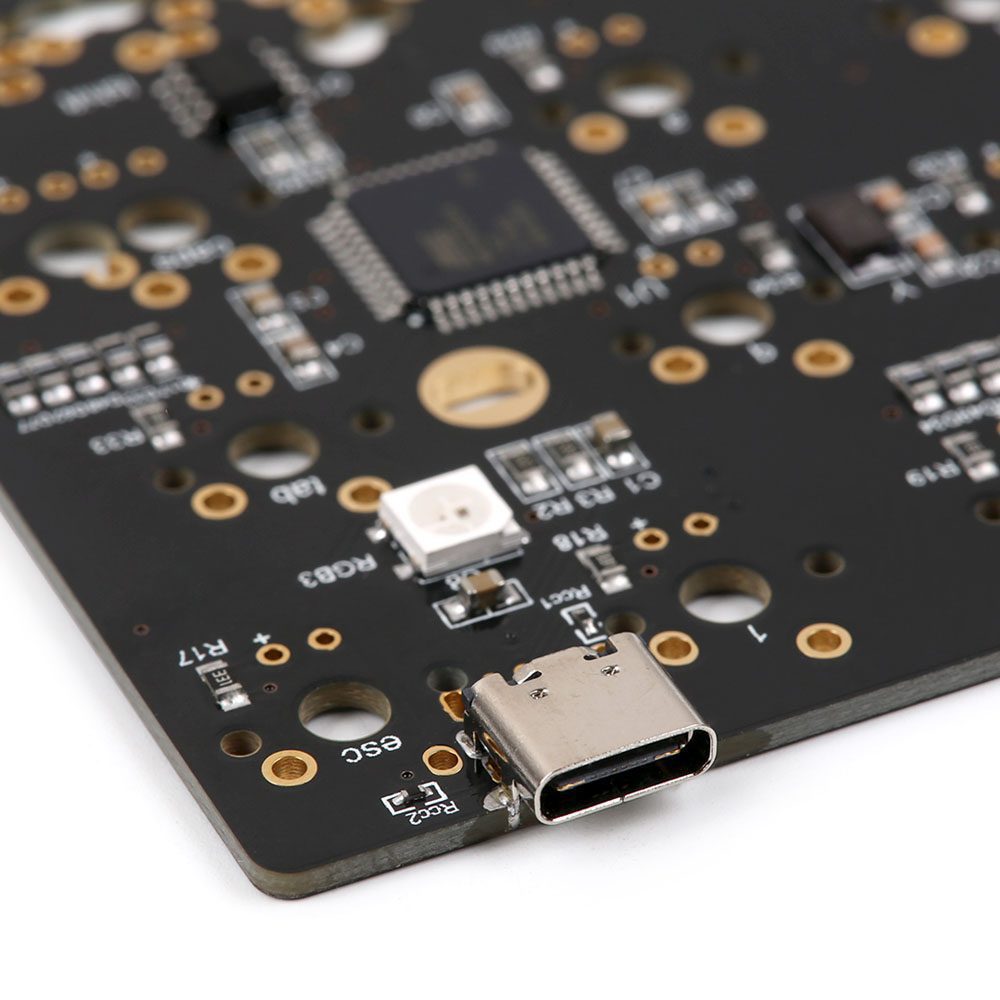

In addition, Keyboard PCBs must be able to accommodate a variety of components depending on what type of keyboard is being created. For example, if a gaming keyboard is being made then it would require additional features such as multiple USB ports or audio jacks as well as backlighting capabilities. Keyboard PCBs must also be designed to accommodate any special functionality that may be required; this could include extra buttons for macros or hotkeys as well as dedicated media keys for controlling playback or volume settings.

Factors to consider when designing Keyboard PCBs

When designing Keyboard PCBs, there are several important factors that must be taken into consideration in order to create an efficient design. Power consumption is one of the most important considerations; Keyboard PCBs need to be designed in such a way that they use as little power as possible while still providing the necessary features.

Signal integrity is also essential; Keyboard PCBs must be designed so that signals are transmitted without any loss or degradation. Physical size constraints are another key factor; Keyboard PCBs must fit within the available space in the keyboard chassis and should not interfere with other components. Cost effectiveness is also critical, as too many components can quickly increase costs while too few can lead to poor performance or insufficient functionality from the Keyboard itself.

In addition, designers must consider ease of assembly when designing Keyboard PCBs. This includes selecting components that are compatible with each other and making sure all connections are properly secured. As keyboards become more complex, Keyboard PCBs also need to accommodate a variety of components depending on what type of keyboard is being created. For example, if a gaming keyboard is being made then it would require additional features such as multiple USB ports or audio jacks as well as backlighting capabilities. Keyboard PCBs must also be designed to accommodate any special functionality that may be required; this could include extra buttons for macros or hotkeys as well as dedicated media keys for controlling playback or volume settings.

Aside from these considerations, Keyboard designers should also think about how their designs will affect user experience when creating Keyboard PCBs. Features like tactile feedback, tactile recognition and haptic feedback capabilities can make using a Keyboard much more enjoyable for users but require specific design choices on the part of designers in order for them to work properly. Quality assurance testing is another important step in ensuring a successful Keyboard design – designers should test their Keyboard prototypes thoroughly before going into production in order to identify any potential problems before they become an issue down the line.

Finally, it’s important to remember that Keyboard designs will evolve over time so it’s essential that designers stay up-to-date with industry trends and developments in order to ensure their designs remain relevant and effective for years to come. With so many factors to consider when designing Keyboard PCBs, experience working with these components is invaluable in creating efficient designs that meet user requirements and manufacturer standards while still providing an enjoyable user experience.

Design process for Keyboard PCBs

The design process for Keyboard PCBs is highly complex and requires careful consideration of a variety of factors. First and foremost, designers must identify the major components that will be present on the Keyboard PCB; this includes evaluating the power requirements of the Keyboard, as well as any additional features such as audio jacks or backlighting. After identifying all of the necessary components, it’s important to consider whether or not they are compatible with each other and to ensure there is enough space on the Keyboard PCB for them all to fit.

Once all components are selected and laid out, Keyboard designers must then evaluate signal integrity by simulating how signals will be transmitted between different parts of the Keyboard. This helps ensure that signals are not lost and that Keyboard performance is not compromised in any way due to poor signal quality. After ensuring signal integrity has been met, designers can begin creating a 3D model of the Keyboard PCB which can then be printed out or simulated in software so that they can test different layouts and make modifications if needed before finalizing their design.

Once a satisfactory layout is achieved, Keyboard PCBs move onto production where various tests are conducted to ensure quality assurance standards are met. This includes testing for electrical properties such as current leakage, capacitance and inductance; thermal properties such as temperature coefficient; mechanical properties like contact resistance; along with visual inspections for any defects or irregularities. Once production has been completed, Keyboard PCBs typically undergo a series of tests including an EMC scan which helps detect any potential interference issues from external sources like cell phones or Bluetooth devices.

In addition to these steps in the design process, Keyboard designers should also think about user experience when creating their designs. Features like tactile feedback and haptic feedback capabilities can make using a Keyboard much more enjoyable for users but require specific design choices on the part of designers in order for them to work properly. Quality assurance testing is another important step in ensuring a successful Keyboard design – designers should test their Keyboard prototypes thoroughly before going into production in order to identify any potential problems before they become an issue down the line.

Finally, while it’s tempting to focus solely on designing efficient Keyboard PCBs with high performance capabilities, it’s essential that designers keep in mind ergonomics when working on these projects – comfort is key when it comes to making sure users enjoy using their keyboards over long periods of time without suffering from discomfort or fatigue due to incorrect positioning or poorly designed keys and switches. By taking into account all these factors throughout the entire design process for Keyboard PCBs, experienced Keyboard engineers can create efficient designs that meet user requirements while still providing an enjoyable user experience overall.

Common mistakes made when creating Keyboard PCBs

Common mistakes made when designing Keyboard PCBs can be prohibitive to the success of a Keyboard. One of the most common errors is failing to properly consider signal integrity. Poorly designed Keyboard PCBs can suffer from poor signal transmission which results in delays, glitches or even complete Keyboard failure. To prevent this issue, designers must simulate their Keyboard PCBs and make sure that signals pass through properly before going into production.

Another mistake Keyboard designers often make is not accounting for user experience when designing their Keyboard PCBs. This can result in a Keyboard that is difficult to use, with keys that are too stiff or too soft, and switches that don’t provide enough tactile feedback or resistance. In order to ensure the ergonomics of the Keyboard are suitable for users, designers should take into account factors such as key travel distance, actuation force and switch type when laying out their designs.

A third common mistake made by Keyboard designers is not testing their design thoroughly before going into production. Quality assurance tests are essential for evaluating how a Keyboard PCB will perform under various conditions; this includes conducting electrical tests such as measuring current leakage, capacitance and inductance; thermal tests such as temperature coefficient measurements; mechanical tests like contact resistance; along with visual inspections for any irregularities in soldering or defects on the Keyboard itself. Without thorough testing prior to production, any problems with the design could remain undetected until it’s too late – leading to wasted time and money spent on redesigning and re-manufacturing faulty hardware components.

Finally, many designersexperience errors due to a lack of familiarity with specific Keyboard components or due to incorrectly selecting components based on cost rather than performance requirements. Designers should make sure they research all available options thoroughly before making any final decisions about components so they can ensure they’re selecting ones compatible with each other and suitable for meeting any given power requirements. Furthermore, it’s important for designers to understand each component’s capabilities so they can avoid selecting an inefficient option which may wind up costing more in the long run if it fails prematurely due to its own limitations.

By avoiding these common mistakes when creating Keyboard PCBs, experienced engineers can ensure their designs meet both user experience and quality assurance standards while also providing efficient performance at an affordable cost over time – enabling consumers everywhere to enjoy high-quality keyboards that offer optimal typing experiences without compromising on safety or reliability.

Tips for creating efficient Keyboard PCB designs

Creating efficient Keyboard PCB designs requires careful and thoughtful consideration of several factors. To ensure success, Keyboard designers should consider the following tips when designing their Keyboard PCBs.

First, Keyboard designers must account for signal integrity when designing their Keyboard PCBs. This involves simulating the Keyboard design to check that signals pass through properly, as poor signal transmission can cause delays and glitches which will significantly decrease performance. Additionally, Keyboard designers should pay special attention to the trace width and spacing between traces in order to ensure they are sufficient enough to support the current requirements of the Keyboard system.

Second, Keyboard engineers should consider ergonomic factors such as key travel distance, tactile response and actuation force when designing their keyboard layout. This ensures that users have an enjoyable typing experience by providing an intuitive mechanical layout with a comfortable stroke distance and adequate resistance for each key press. Additionally, it is important to select switches that are optimized for noise reduction so as not to disrupt user concentration or productivity.

Third, Keyboard designers should conduct thorough quality assurance tests prior to production in order to detect any irregularities in soldering or defects on the Keyboard itself. These tests should include electrical measurements such as current leakage and capacitance; thermal tests like temperature coefficient measurements; mechanical tests such as contact resistance; along with visual inspections for any abnormalities on the hardware components themselves.

Fourth, Keyboard engineers must be knowledgeable about specific Keyboard components before selecting them – this includes researching all available options thoroughly before making any final decisions about components so they can ensure they’re selecting ones compatible with each other and suitable for meeting any given power requirements. Furthermore, Keyboard engineers must understand each component’s capabilities so they can avoid selecting an inefficient option which may wind up costing more in the long run if it fails prematurely due to its own limitations.

Finally, Keyboard designers must make sure every component within their design is well integrated in order to maximize efficiency while minimizing unnecessary cost outlays. By keeping these tips in mind during every stage of the design process from concept through production testing – experienced Keyboard engineers can create efficient designs that meet user requirements while still providing an enjoyable user experience overall.

Conclusion

Keyboard PCB design is a complex process that requires engineers to consider several factors in order to ensure their designs meet both user experience and quality assurance standards. By following our tips for creating Keyboard PCBs, experienced Keyboard designers can make sure they are optimizing every aspect of the design from signal integrity through component selection and integration – allowing them to create efficient Keyboard PCBs with optimal performance at an affordable cost over time. With these principles in mind, Keyboard users everywhere will be able to enjoy high-quality keyboards offering an enjoyable typing experience without compromising on safety or reliability.